Created by Webmasterdesigner - © 2025 All right reserved

VANTAGGI DELLA GASSIFICAZIONE AL PLASMA DEI RIFIUTI

La nostra gassificazione al plasma dei rifiuti offre numerosi vantaggi unici rispetto alle tecnologie convenzionali di trattamento termico.

Massima efficienza energetica convertendo i rifiuti in gas per generare elettricità direttamente in motori a gas, turbine a gas o celle a combustibile, migliorando notevolmente l'efficienza della conversione energetica e massimizzando la produzione elettrica.

Il gas può anche essere convertito in gas naturale sostitutivo, per la distribuzione a case e aziende nelle reti del gas esistenti, elettricità, calore, vapore, fertilizzanti o in combustibili liquidi.

MASSIMA DEVIAZIONE DALLE DISCARICHE

La nostra tecnologia e il nostro processo consentono quasi la totale deviazione dalla discarica e sono complementari al riciclaggio. Può essere utilizzata in combinazione con i sistemi di riciclaggio esistenti e, dopo la rimozione dei materiali riciclabili, prende i rifiuti che non possono essere riciclati e li utilizza per produrre energia.

Il processo produce un materiale da costruzione di alto valore chiamato SLAG che è riconosciuto come prodotto e non come rifiuto. Questo elimina qualsiasi rischio ambientale, normativo e commerciale, che sono associati alle preoccupazioni per la potenziale eco-tossicità delle ceneri pesanti prodotte dagli inceneritori e da altri processi termici.

IL NOSTRO SISTEMA DI GASSIFICAZIONE AL PLASMA DEI RIFIUTI È IN GRADO DI TRATTARE QUALSIASI TIPO DI RIFIUTO INSIEME

Rifiuti solidi urbani (inclusa la frazione umida);

RDF;

Residui della lavorazione del legno, biomassa;

Traversine ferroviarie;

Rifiuti ospedalieri;

Plastica, imballaggi, rifiuti di PVC e polietilene;

Rifiuti farmaceutici e fanghi;

Rifiuti chimici e fanghi da trattamenti chimici;

Pneumatici usati;

Scarti dalla lavorazione della pelle;

Oli esausti, oli contaminati; assorbenti in polipropilene e naturali;

Rifiuti industriali contenenti cloro, zolfo, ecc.;

Oli industriali e residui di fanghi di lavaggio serbatoi;

Segatura, fanghi e ceneri da impianti di termovalorizzazione;

Amianto;

Filtri diesel da auto, navi e vari veicoli;

Filtri dell’olio da veicoli a motore;

Rifiuti elettronici speciali (computer, monitor, elettrodomestici, ecc.);

Batterie, acidi;

Rifiuti esplosivi;

Rifiuti contenenti fosforo;

Rifiuti militari;

Ceneri volanti e ceneri pesanti;

Altri rifiuti pericolosi.

BASSO IMPATTO AMBIENTALE E VISIVO

Il nostro impianto è alto circa 15 m, il che significa che può essere inserito in un magazzino standard simile a quelli che si trovano nelle aree industriali ai margini della città. Le emissioni dell'impianto sono molto basse, consentendo una ciminiera di soli circa 10 metri sopra l'altezza dell'edificio. Quando si producono carburanti, le emissioni locali sono trascurabili e non è necessaria alcuna ciminiera.

SOLUZIONI LOCALI

Il basso impatto ambientale significa che un impianto può essere situato, in modo discreto, ai margini di una città, ricevendo i rifiuti di quella città e fornendo in cambio energia elettrica e calore - una soluzione locale e comunitaria alle sfide della gestione dei rifiuti locali e alle esigenze di energia sostenibile.

Collocare un impianto vicino ai centri abitati offre ulteriori vantaggi, come la riduzione dell’impronta di carbonio dei rifiuti grazie alla diminuzione delle distanze di trasporto. Inoltre, posizionare gli impianti vicino agli utenti di calore, siano essi industriali o domestici, migliora ulteriormente l’efficienza energetica.

DISTRIBUZIONE RAPIDA

Poiché la maggior parte delle apparecchiature viene prodotta fuori sede, un impianto può essere costruito e installato in 18 mesi rispetto ai 24-30 mesi richiesti dalle tecnologie alternative, che di solito necessitano di una notevole quantità di lavori di fabbricazione in loco.

LA NOSTRA TECNOLOGIA DI GASSIFICAZIONE AL PLASMA DEI RIFIUTI

Il cuore della tecnologia è un processo di conversione avanzato a due stadi. Combina due tecnologie di lunga data e ben collaudate (gassificazione e conversione al plasma) in una configurazione unica.

Dopo la rimozione dei materiali riciclabili di valore, il processo Gasplasma tratta un'ampia gamma di materie prime non riciclabili prodotte dai rifiuti solidi urbani residui e dai rifiuti commerciali/industriali, convertendoli tutti in due prodotti di alto valore: un gas di sintesi pulito, di alta qualità e ricco di energia (syngas) e un prodotto solido vetrificato, la SCORIA – ciascuno con molteplici applicazioni.

La nostra tecnologia offre una soluzione davvero rivoluzionaria per un futuro a zero rifiuti.

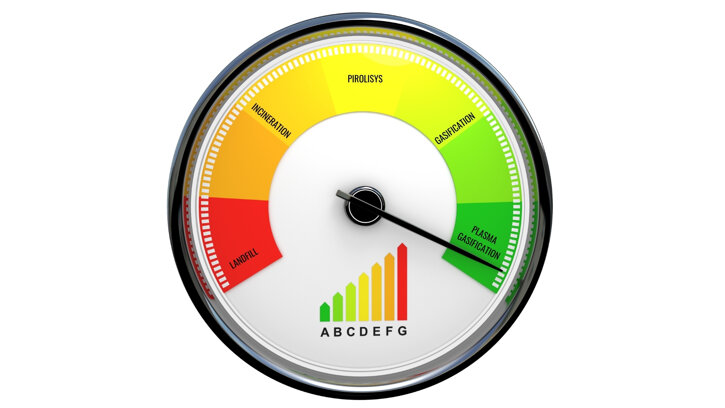

Vedi lo schema seguente "Best Green Technologies" per lo smaltimento dei rifiuti:

COMPONENTI DI UN IMPIANTO COMPLETO DI GASSIFICAZIONE DEI RIFIUTI AL PLASMA

Un impianto completo di gassificazione al plasma dei rifiuti comprende:

1) Una sala di ricezione dei rifiuti e un impianto di riciclaggio dei materiali (MRF);

2) La tecnologia principale Gasplasma costituita dal gassificatore a letto fluido e dal convertitore al plasma;

3) Apparecchiature di pulizia del gas per raffreddare, pulire e condizionare il syngas;

4) Un'isola di potenza per generare energia rinnovabile e calore o la trasformazione del syngas ottenuto in altri prodotti.

Il gassificatore a letto fluido trasforma i materiali organici nel materiale di alimentazione in un syngas grezzo o non raffinato; questo avviene a una temperatura di circa 800 °C in un ambiente a ossigeno ridotto e controllato. Il syngas prodotto dalla sola gassificazione contiene catrami condensabili che lo rendono inadatto all'uso in motori a gas efficienti o turbine a gas.

PRODOTTI DALLA GASSIFICAZIONE AL PLASMA DEI RIFIUTI

Il syngas grezzo viene quindi alimentato in un convertitore al plasma separato e secondario. L’intenso calore dell’arco al plasma e la forte luce ultravioletta del plasma ‘rompono’ gli ars condensabili e altri composti organici a catena lunga in un syngas pulito e ricco di idrogeno.

La cenere pesante proveniente dal gassificatore, contenente principalmente elementi inorganici, viene anch’essa alimentata nel convertitore al plasma e viene vetrificata in un prodotto chiamato SLAG. Questo è un materiale meccanicamente resistente ed estremamente resistente al dilavamento con molteplici applicazioni (in contrasto con la cenere pesante derivante da altri processi termici di trattamento dei rifiuti).

POWER ISLAND (WASTE TO ENERGY)

Il syngas viene quindi raffreddato, pulito e condizionato tramite scrubber convenzionali a umido e a secco (per rimuovere eventuali componenti acide) prima di essere utilizzato direttamente in una power island, composta da motori a gas alternativi o turbine a gas, per generare energia e calore rinnovabili da esportare. Presso il suo impianto, ITC gestisce un motore a gas alimentato a syngas dal 2008.

Mentre il mondo cerca nuove soluzioni sostenibili per la gestione dei rifiuti e fonti alternative di energia rinnovabile, la nostra tecnologia offre una soluzione di livello mondiale a entrambe queste sfide globali.

LA GASSIFICAZIONE NON È INCENERIMENTO

VANTAGGI DELLA GASSIFICAZIONE AL PLASMA

SYNGAS E PRODOTTI ENERGETICI

ITC LTD

MAPPA DEL SITO

MAPPA DEL SITO

International Technical Consultants Ltd

19 Leyden Street

London - E1 7LE

United Kingdom

Company Reg. 04555793

Vat: GB843855596

◙ INDIRIZZO LEGALE

■ Home

■ Gassificazione al plasma dei rifiuti

■ La gassificazione non è incenerimento

■ Vantaggi della gassificazione al plasma

■ Syngas e prodotti energetici

■ Serra sterile

■ Serra sterile - La struttura

■ Serra sterile - Vantaggi

■ Soluzioni di illuminazione a LED

■ Edifici ecologici

CONTATTI

info@itcltd.net

itcltd2@gmail.com

■ Energia Rinnovabile

■ Trattamento delle Acque

■ Servizi

■ Contatto

■ Scaricad

■ Privacy Cookies Policy

Creato da Webmasterdesigner - © 2025 Tutti i diritti riservati